F6100 Safe-Air Monitor for Breathing-Air Systems

The F6100 Safe Air Monitor is the ideal instrument for those requiring continuous monitoring of their breathing-air supply. Supplied with a wall mounting kit, connection hose and coupling the F6100 is designed to be connected via a T fitting to the breathing-air supply.

Once set up the instrument will continue to monitor and data log the air quality at user defined intervals validating the air quality against a range of alternative international standards. In the UK this ensures complete compliance with the relevant requirements of COSHH. The F6100 is mains powered via an adaptor which is supplied with the instrument, in case of a power failure an inbuilt rechargeable battery back-up system will provide an additional 30 minutes operating time. The instrument has an intuitive touch screen display, making set up and retrieval of previous test results easy and quick to complete.

The F6100 incorporates electronic cells for measuring carbon monoxide, carbon dioxide, and oxygen. Moisture levels

within the breathing air are measured by a dewpoint sensor. The instrument then displays the moisture content in

pressure or atmospheric dewpoint levels, as well as providing the concentration in mg/m3. It also includes digital

airline pressure and ambient temperature readings.

Oil measurements are completed using the Draeger Impactor, which is inserted into a test port on the instrument. The F6100 provides a prompt to the user whenever an oil Impactor test is required and the time interval can again be defined by the user in the set up. The Impactor has no glass or hazard components and can test for all known synthetic and mineral oils. This port is also compatible with a range of additional Draeger chemical reagent tubes, with test times which can be programmed via the menu, to identify other potential contaminants.

The instrument has 2 no. 4-20mA inputs to display and record results from remote sensors (not supplied as standard with the instrument). Factair offers a separate sensor module which can be configured for a range of user defined contaminants. If airflow rate monitoring is required, the unit can be connected to a remote flowmeter and this can then assist with the requirements to audit compressed-air systems for energy efficeny as described in ISO11011.

Each test, is stored within the F6100’s memory and can be retrieved on screen and transferred via a removable SD card. A software program is provided which provides a convenient way to analyse the datalogged results and identify trends and occasions when the breathing-air failed to meet the selected standard. The F6100 also includes a volt free contact which can be connected to a BMS system or a remote alarm to alert users when air quality fails to meet the required standard.

The instrument is designed to monitor low-pressure airline breathing systems it can also be used with the F3002 high- pressure regulator assembly to monitor HP systems. Factair’s quality accredited instrument workshop provides recalibration and servicing for the unit.

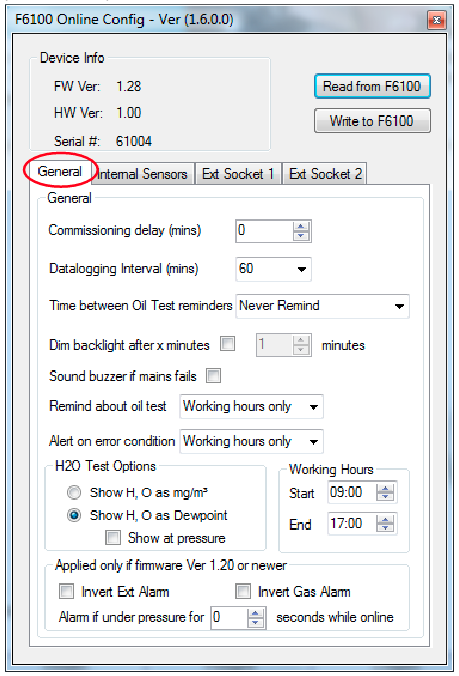

The F6100 is provided with easy to configure PC software which allows the user to set up the readings for the instrument. This software is available to download from Factair’s website.

The general tab allows you to configure a range of settings, these include: Commissioning delay, which allows you to set a time interval before the instrument first begins to record

results; datalogging interval; working hours and how the water readings are displayed i.e. mg/m3, atmospheric or pressure dewpoint.

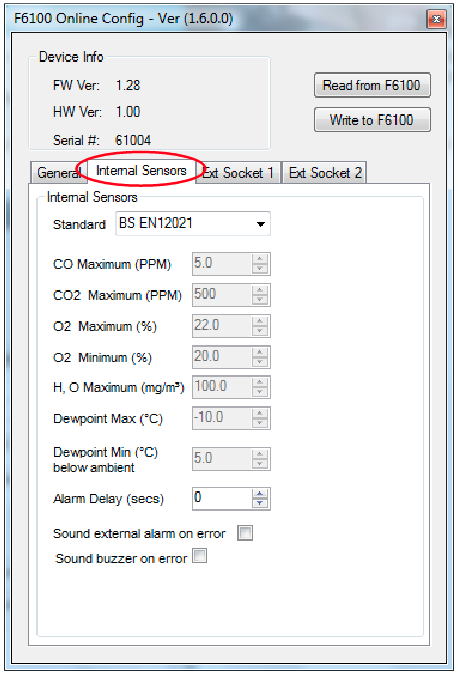

The internal sensors tab allows you to choose the test standard or enter your own custom levels. From this screen you can also choose whether you want to activate the volt

free contact which can then be used for an external alarm or to control the shutdown of the compressor

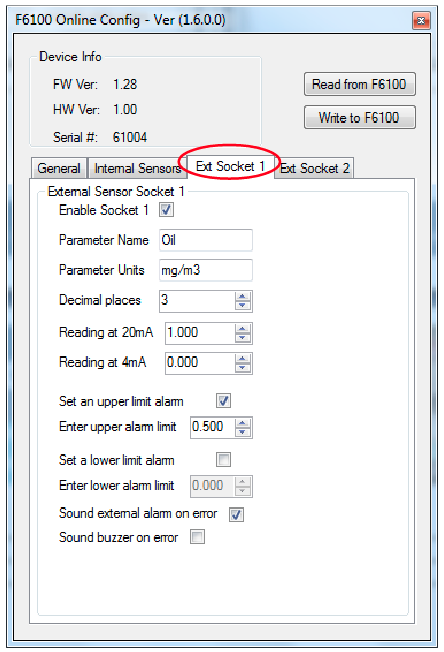

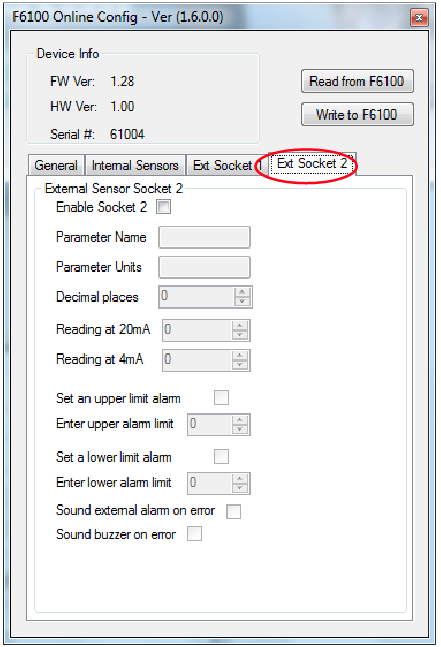

If you connect additional external sensors with 4 to 20mA signals these are configured from the following tabs, in the example below ‘Ext Sensor Socket 1’ has been configured for the F6300 Oil Vapour Monitor.

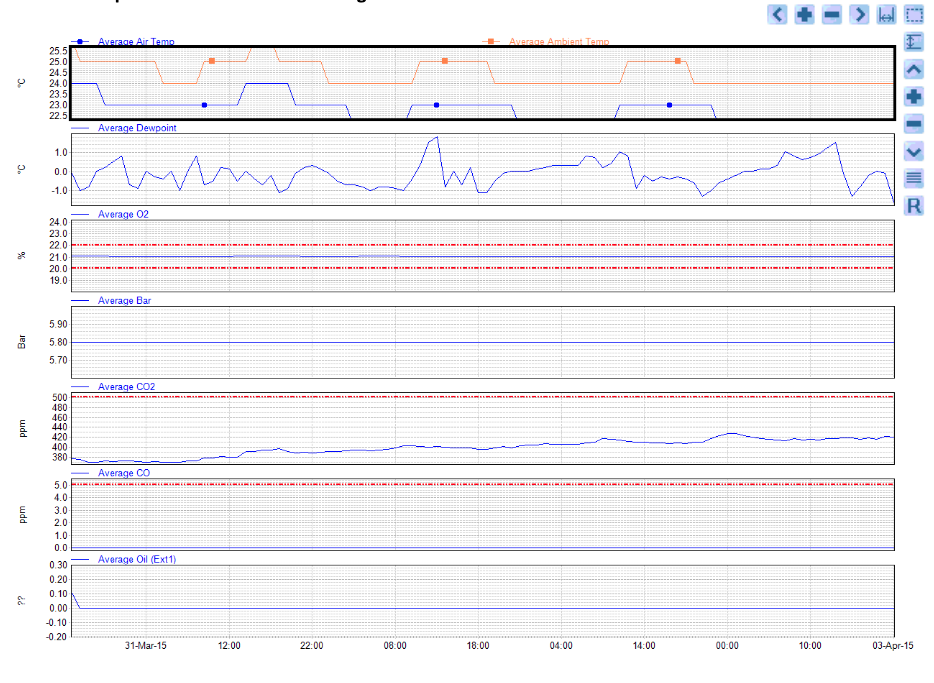

Also supplied with the F6100 is datalogging software which makes it easy to analyse results, identify trends and exceptions. Results can be imported into the software and then individual or a range of sensor readings reviewed across a selectable date range. The screen dump from the following page is an example of the how the software displays the results.

The results on the instrument’s SD card are in a CSV format, which also allows them to be easily read by spreadsheet software such as Microsoft Excel.

Screen dump from F6100 Data Monitoring Software

|

Model |

Width |

Height |

Depth |

Weight |

Power |

Pressure |

External Connections |

|

F6100 |

210mm |

215mm |

75mm |

1.6 Kg |

110-240V, 1ph 50/60Hz |

2 – 10 bar |

2 no. 4-20mA External Sensors – 2 wire 1 no. Volt Free Contact Test port for Draeger Impactor/Tubes |

Other Breathing-Air Quality Test Instruments

F6300 Oil Vapour Monitor

This oil vapour monitor is designed to be used either as a stand-alone instrument or in conjunction with the F6100 Safe-Air Monitor. Featuring a metal oxide sensor which is specially optimised to recognise long chain hydrocarbons this instrument has a calibrated detection range down to 0.01 mg/m3.

F6000 Safe-Air Tester

Designed to provide sample point testing, rather than continuously on-line monitoring, the F6000 features the same key features as the F6100 but with an additional in built electronic flowmeter. Test results can be downloaded via a USB cable to a PC.