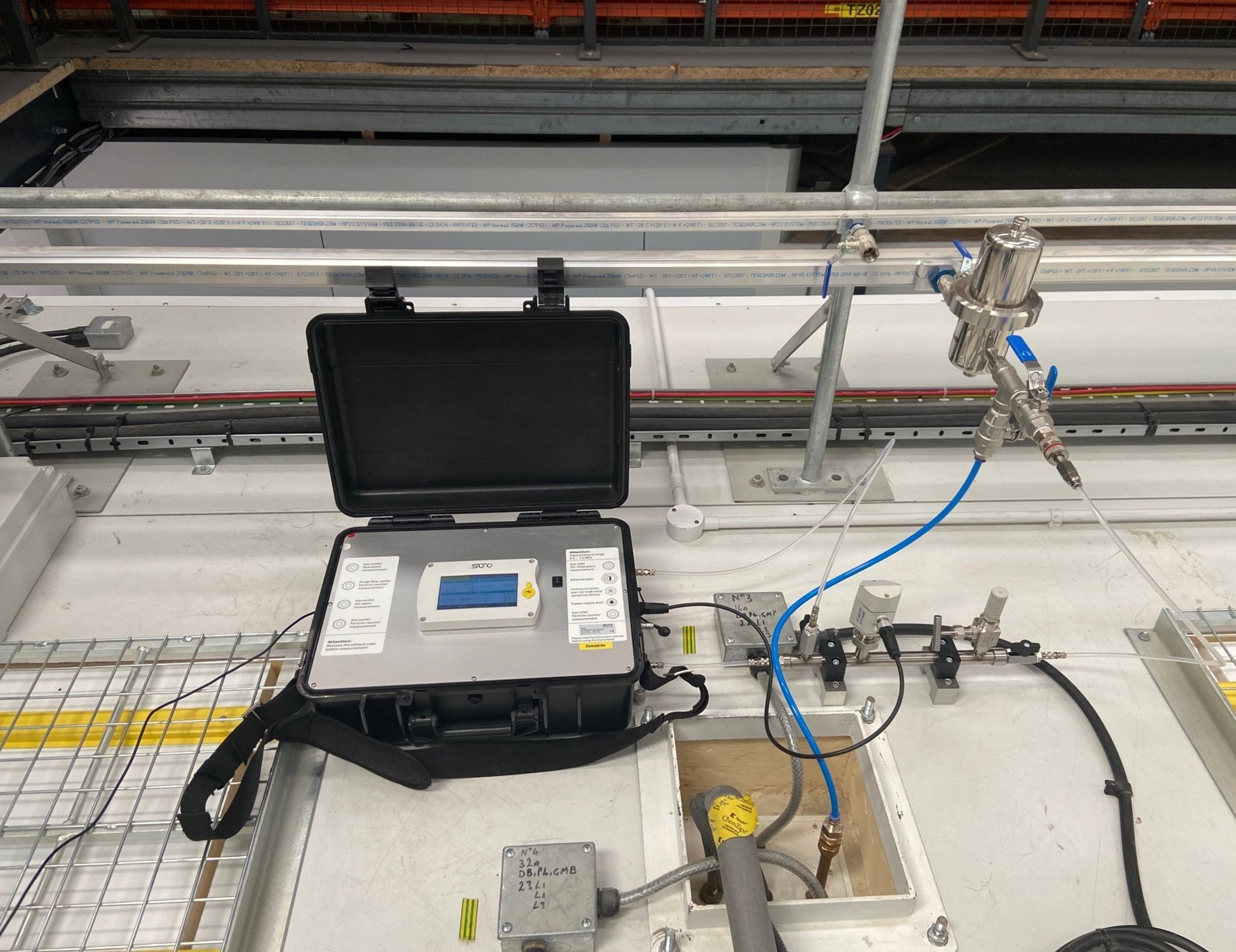

Compressed Air Testing

With extensive experience in compressed air systems, Factair can offer on site point of use testing and datalogging of your compressed air system, using calibrated instruments certified by TÜV SÜD.

Particulate

Using a laser particle counter with isokinetic probe connected to your compressed air outlet.

Particle counts in 3 size ranges: 0.1-0.5µm, 0.5-1.0µm and 1.0 to 5.0µm

Moisture

Using an electronic dewpoint meter we can measure between a pressure dewpoint of -100 and +20°C.

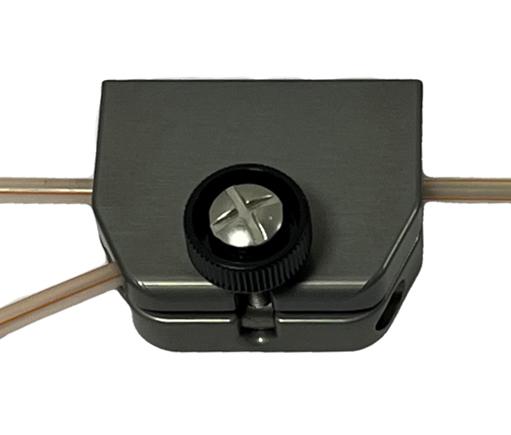

Oil

Initial testing using an oil impactor connected to your compressed-air outlet to confirm there is no oil aerosol present at greater than 0.05 mg/m³.

Follow up test with PID sensor to detect oil vapour and other volatile organic compounds to a lowest detection threshold of 0.003 mg/m³.

At the end of the test a full written report is provided with contaminants expressed in the terms of the class levels specified in ISO8573-1. Being point of use testing results are indicative and do not follow the methodology specified in ISO8573 parts 2 to 9.