BA800D 4-Outlet breathing air compressor

The BA800D utilises a sophisticated, fuel efficient, variable speed engine drive system that runs at the optimum speed to match the breathing-air demand of up to 800 l/min at 8 bar it incorporates breathing-air filtration with a pressure swing dryer CO and CO2 suppression system. BA800D's feature FACTAIR’s ‘fail-safe’ system providing automatic back up from high-pressure cylinders, ensuring a safe exit from the workplace in the event of failure of the primary supply.

The breathing-air is delivered through 4 fixed pressure, flow protected outlets, for positive pressure demand masks, with

a switchable option to allow a regulated supply for constant flow devices. In addition a larger diameter single outlet is fitted for breathing air to be delivered to a remote distribution system.

The unit also incorporates volt free contacts to interface with external alarm/shut down devices and a sophisticated minimum loss control system for the HP reserve. The BA800D has been designed to work in wide range of demanding environments with a sand trap louvre ventilation and a specially uprated cooling system allowing the units to operate in both hot and dusty conditions. In addition, as standard, the units are fitted with Chalwyn valve, spark arrestor and a high-level air intake to ensure that air is drawn in from an area clear of exhaust gases.

Air quality exceeds the criteria laid down in BS EN12021 and units are built in our Quality Assured workshops under procedures approved to ISO 9001. Both units have European Community Whole of Vehicle Type Approval 2007/46/EC as well as complying with EC noise regulations of 97LWA.

SPECIFICATION

ENGINE Lombardini LDW 1003, 3-cylinder, water-cooled diesel engine c/w spark arrestor and Chalwyn overspeed valve.

COMPRESSOR Mattei M80 rotary vane (13bar maximum pressure)

OPERATING SPEED 2,000rpm minimum to 3,000rpm maximum (variable speed control based on demand)

AFTERCOOLER Outlet temperature within 5°C of ambient

FILTRATION Purifies air to breathing quality conforming to EN 12021. Pressure swing dryer reducing the dewpoint to –40°C and provides CO and CO2 suppression

BA OUTPUT CAPACITY 540 to 800LPM. @ 8 Bar

TOTAL CYL. CAPACITY 4 off 9 litre 200bar HP cylinders. 7,200 litres storage capacity. or 4 off 9 litre 300 bar HP cylinders, 10,800 litres storage capacity

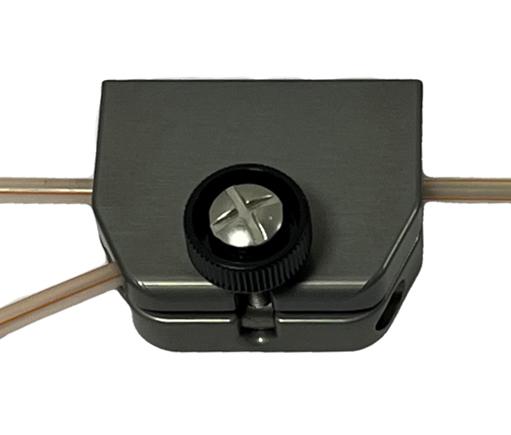

OUTLETS 4 off Draeger/Scott compatible couplings, switchable between:- Fixed pressure flow protected for demand masks Regulated pressure for constant flow devices.

1 off ½" CEJN 442 high flow non-regulated coupling.

CHASSIS Approved to 2007/46/EC road towing under 750kg.

DIMENSIONS Length <3500mm, Width 1440mm, Height 1550mm

ENCLOSURE Gull wing type doors for easy access, sand trap ventilation louvres to reduce enclosure

contamination.

TOWING HITCH 50 mm bal

BATTERY 12 volt DC – Negative earth

STANDARD FEATURES Lifting eye · Spark arrestor, High-level air intake and hours run meter, Fully automatic ‘fail-safe' reserve from high-pressure cylinders with start up protection. Electronic minimum air loss HP cylinder control system. Engine shut-down activated by either high temperature compressor oil or low engine oil pressure. Fuel tank 8 hours run

time complete with low fuel alarm/start prevention.

GAUGES SHOW HP cylinder pressure · System pressure · Regulated pressure

LED INDICATORS Glow plug, low fuel warning, cylinder status

AUDIBLE ALARMS Primary air supply failure. Air reserve inadequate and low fuel level

VISUAL ALARMS Primary air supply failure. Air reserve inadequate and low fuel level

ALARM INTERFACE Volt free contacts to accept alarm input from external alarm, shut down devices*

ALARM DATA Full alarm event log downloadable via USB port

ENVIRONMENTAL Oil tight chassis. Condensate vaporised in engine exhaust.

NOISE LEVEL <97 LWA. (Better than 77dBA @ 4 metres)

WASTES Discharge from oil removal filter autodrains gathered into a container for proper disposal

QUALITY BA800D manufactured in accordance with our Quality Assurance Procedures approved to ISO9001.

* - Unit will need to be configured to suit specified devices.